The company specializes in the production of plastic packaging bags. Such as express bags, OPP bags, PE ziplock bags and zipper bags.

Industry Knowledge Extension

More Information About Vacuum bag

How vacuum bags are made?

Vacuum bags are typically made from a combination of plastic and nylon materials, and they are designed to be used with vacuum sealing equipment to remove air from the bag and create an airtight seal around the contents. Here is a general overview of how vacuum bags are made:

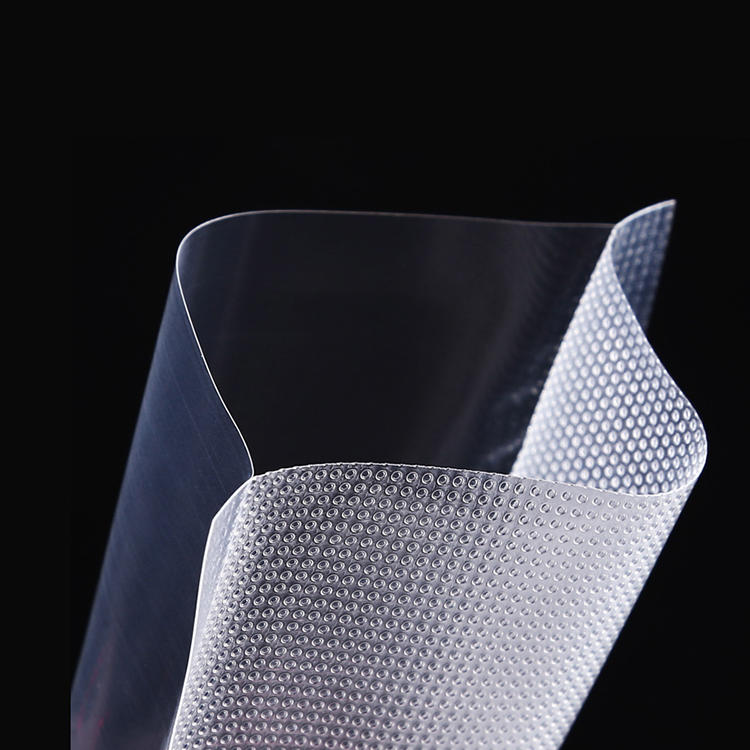

Material selection: The materials used to make vacuum bags typically include a layer of polyethylene plastic for strength and a layer of nylon for puncture resistance and flexibility. The thickness and type of material can vary depending on the intended use of the bag.

Film extrusion: The plastic and nylon materials are extruded in a continuous process to create a flat sheet of material that will be used to make the bags. This process involves melting the materials and passing them through a die to form a thin, flat film.

Bag production: The flat sheet of material is then fed into a bag-making machine that cuts and seals the material to create individual bags. The machine first cuts the material to the desired size, then folds and seals the sides of the bag, leaving an opening at the top for the contents to be inserted.

Printing and labeling: Once the bags are formed, they may be printed with information such as product name, branding, or instructions for use. Labels or stickers may also be applied to the bags.

Packaging and distribution: The finished vacuum bags are then packaged in boxes or other containers for distribution to retailers or end-users.

Overall, the manufacturing process for vacuum bags involves a combination of material selection, film extrusion, bag production, printing, and packaging. The precise details of the process may vary depending on the specific manufacturer and the intended use of the bags.

The importance of vacuum bags

Vacuum bags have several important benefits and are widely used in a variety of settings. Here are some of the key reasons why vacuum bags are important:

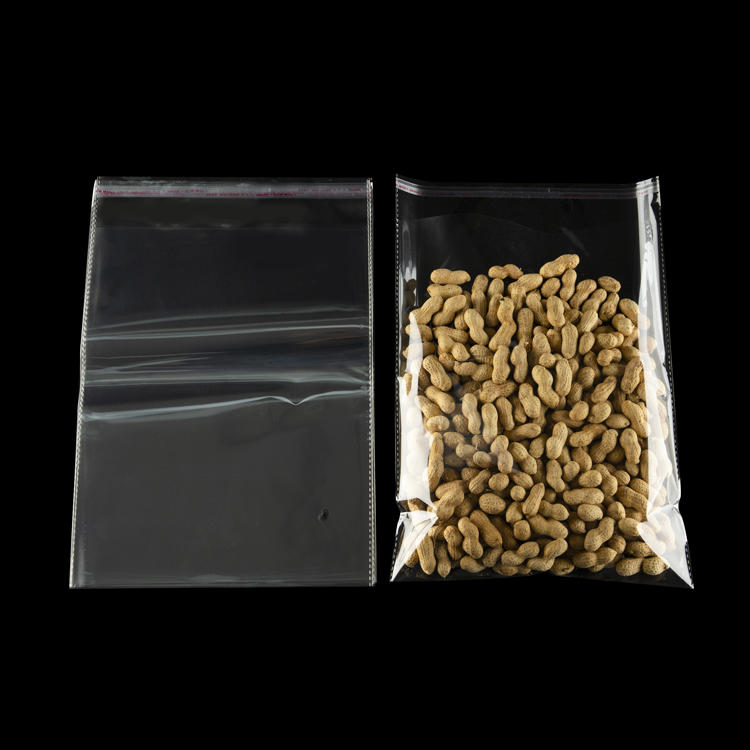

Preservation of food: Vacuum bags are commonly used to store and preserve food by removing air from the bag and creating an airtight seal around the contents. This can help to prevent spoilage, extend the shelf life of perishable foods, and preserve the flavor and nutritional value of the food.

Space-saving: Vacuum bags can be compressed to a fraction of their original size, making them ideal for storing items in small spaces. This is especially useful for bulky items like clothing, bedding, and towels, as well as for travel and camping gear.

Protection from moisture and other environmental factors: Vacuum bags are often used to protect items from moisture, dust, and other environmental factors that can damage or degrade the quality of the item over time. This is especially important for items like electronics, documents, and artwork that are sensitive to moisture and humidity.

Organizational benefits: Vacuum bags can help to keep items organized and easily accessible. By compressing items and storing them in airtight bags, it is easier to stack and store items neatly and efficiently.

Overall, vacuum bags are an important tool for storing, preserving, and protecting a wide range of items. Whether for food storage, space-saving, protection from environmental factors, or organizational benefits, vacuum bags offer many advantages over traditional storage methods.

0

0

English

English 中文简体

中文简体 عربى

عربى