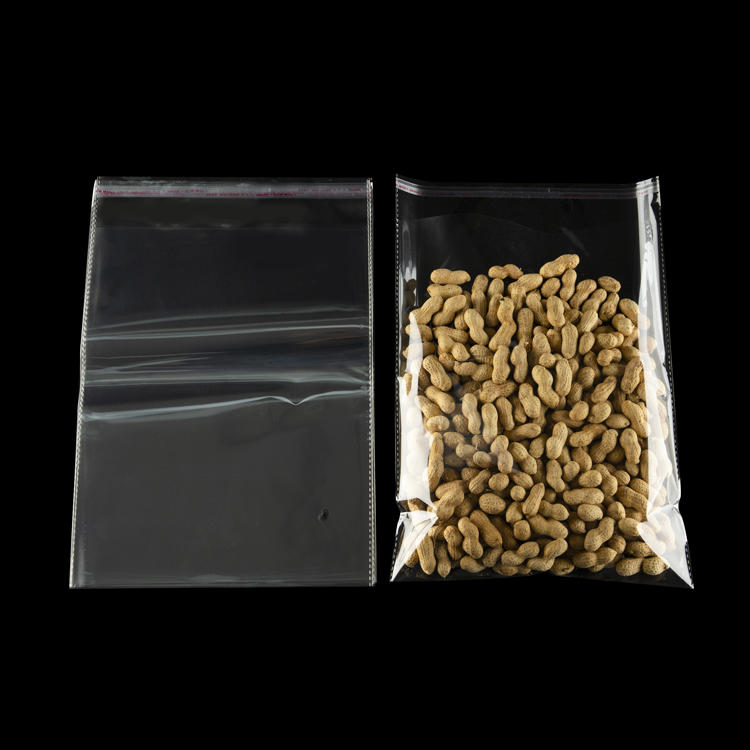

The company specializes in the production of plastic packaging bags. Such as express bags, OPP bags, PE ziplock bags and zipper bags.

Industry Knowledge Extension

More Information About Thermal paper

What is thermal paper?

Thermal paper is a special type of paper that is coated with a heat-sensitive material, usually a mixture of dye and developer. When heat is applied to the paper, the dye reacts with the developer, causing a color change and forming an image or text.

Thermal paper is commonly used in a variety of applications such as point-of-sale (POS) systems, label printing, fax machine and ATM receipts. It is also used in medical equipment such as electrocardiogram machines, and in the transportation industry to print bus tickets and boarding passes.

One of the main advantages of thermal paper is that it does not require ink or tint to print, which can make it a cost-effective option in some applications. Additionally, thermal printers are generally faster and more reliable than other types of printers, making them a popular choice in industries where speed and efficiency are important.

However, thermal paper also has some disadvantages. Images and text printed on thermal paper will fade over time, especially when exposed to heat, light or humidity. This can make it difficult to keep records or important information for long periods of time. In addition, the chemicals used in thermal paper are harmful to the environment, and improper disposal of thermal paper can lead to pollution.

Overall, Thermal paper is a useful and widely used paper type that has advantages in certain applications. However, its limitations and potential environmental impact need to be considered when deciding whether to use it.

How thermal paper is made?

Thermal paper is made by coating a heat-sensitive coating on the surface of ordinary paper. This coating is usually a mixture of dyes, developers, and binders and provides high sensitivity and high contrast.

The manufacturing process of thermal paper generally includes the following steps:

1.Prepare base paper: select pulp, process and treat it, and prepare base paper that meets the requirements.

2.Coating heat-sensitive coating: apply heat-sensitive coating on the surface of base paper, usually by dipping or spraying. Coated paper needs to be dried.

3.Cutting and winding: cutting and winding the dry thermal paper for subsequent printing and use.

The coating process of thermal paper and the choice of coating formula are the key factors affecting the quality of thermal paper. Different coating processes will lead to differences in coating thickness, uniformity and adhesion, so it is necessary to choose a suitable coating process to obtain the required performance. The choice of coating formulation is also important, as different dyes and developers can affect thermal paper characteristics such as sensitivity, contrast and durability.

In general, the manufacturing process of thermal paper is relatively simple, but requires strict process control and quality monitoring to ensure product quality and stability.

What scenarios are thermal paper used for?

Thermal paper is typically used where short-term printing is required, such as point-of-sale (POS) systems, label printing, fax machines, ATM receipts, and more.

The following are some common usage scenarios of thermal paper:

1.Retail: In retail stores, thermal paper is widely used to print receipts and sales notes.

2.Logistics and transportation industry: thermal paper is often used to print shipping labels, barcode labels, delivery documents and shipping tickets.

3.Medical equipment: In medical equipment, thermal paper is commonly used to print electrocardiograms, medical records, and drug labels, among others.

4.Hospitality and Tourism: Thermal paper can be used to print room bills, tickets and access cards, etc.

5.Government and Institutions: In government and institutions, thermal paper is commonly used to print tickets, invoices and forms, etc.

Overall, thermal paper is used in a wide variety of scenarios because of its convenience and cost-effectiveness, and thermal printers are generally faster and more reliable than other types of printers. However, it should be noted that thermal paper has limited durability and is usually only suitable for short-term printing needs, and its impact on the environment needs to be paid attention to.

0

0

English

English 中文简体

中文简体 عربى

عربى